High-Quality Digitizing for Embroidery: Expert Workmanship

High-Quality Digitizing for Embroidery: Expert Workmanship

Blog Article

Understanding the Embroidery Digitizing Refine: Your Ultimate Overview

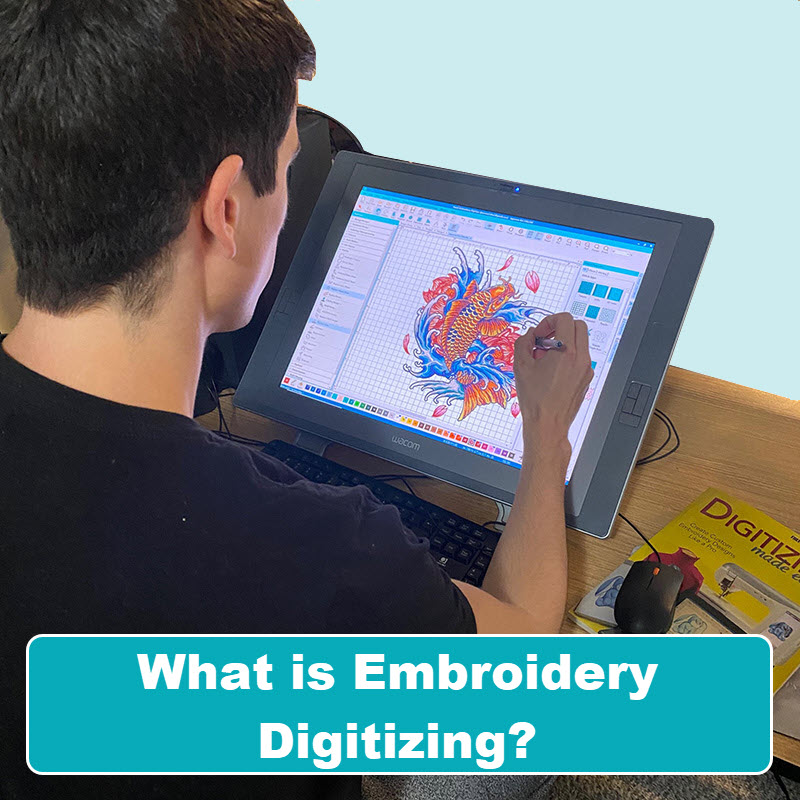

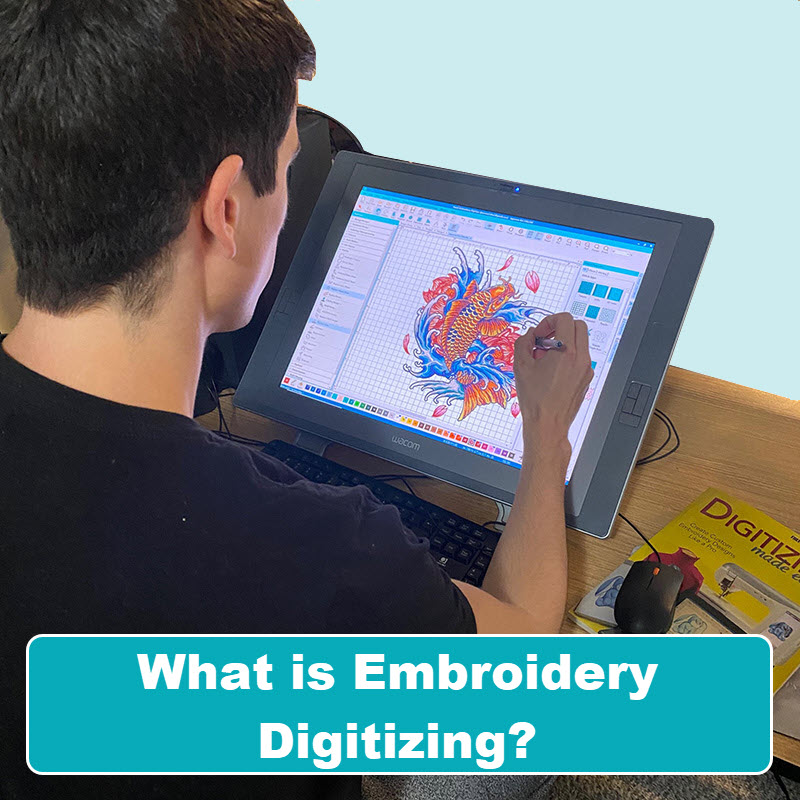

Embroidery digitizing is a careful craft that requires precision and proficiency to translate complex designs into digital layouts for machine embroidery. As craftsmens start this journey to grasp the needlework digitizing procedure, an extensive understanding of the fundamentals establishes the foundation for excellence. Beyond the fundamental knowledge lies a world of innovative software, specialized tools, and nuanced methods waiting to be discovered. By diving right into the nuances of digitizing, one can unlock a world of imaginative opportunities and elevate their embroidery projects to new heights.

Recognizing Needlework Digitizing Essentials

Embroidery digitizing basics form the foundation upon which complex layouts are equated into machine-readable styles for exact sewing. This preliminary step in the embroidery digitizing process is vital for making sure that the last stitched product is a devoted representation of the original design. Understanding embroidery digitizing basics entails grasping key concepts such as stitch kinds, sew instructions, density, underlay, and pull compensation.

Sew types play a vital duty in establishing the aesthetic and textural end result of the stitched style. By choosing the suitable stitch type, whether it be satin, fill, or running stitch, digitizers can achieve the desired effect and boost the general high quality of the needlework. Furthermore, stitch direction affects the circulation and dimension of the design, while thickness establishes the spacing and insurance coverage of the stitches.

In addition, padding sewing gives security to the layout by safeguarding the textile and stopping distortion throughout the embroidery procedure. Draw payment is one more important consideration to neutralize the natural propensity of material to agreement when stitched. Mastering these needlework digitizing basics is basic for creating professional-quality stitched products.

Picking the Right Digitizing Software

Choosing the proper digitizing software is an important choice that considerably affects the performance and quality of the embroidery digitizing process. Digitizing for Embroidery. When selecting the appropriate digitizing software, it is important to take into consideration factors such as the complexity of styles you prepare to produce, the user-friendliness of the software program, the degree of consumer assistance offered, and the compatibility with your embroidery device

There are different digitizing software application alternatives readily available in the market, ranging from basic programs for beginners to advanced software for expert digitizers. Some prominent options consist of Wilcom EmbroideryStudio, Hatch Needlework Software Application, and PulseID. These software supply a vast range of tools and features to help you create elaborate designs effortlessly.

Before choosing, it is recommended to explore the different software alternatives via cost-free tests or demonstrations to identify which one best suits your demands. In addition, checking out evaluations and seeking a knockout post recommendations from seasoned digitizers can give valuable understandings right into the staminas and weaknesses of each software plan (Digitizing for Embroidery). By very carefully reviewing your demands and comparing the attributes of various digitizing software application, you can make an educated choice that enhances your needlework digitizing process

Digitizing Tools and Strategies

Optimizing Style Setup for Needlework

Mastering the complexities of style setups is basic in attaining important link ideal cause the embroidery digitizing process, building upon the foundation laid by understanding digitizing devices and techniques. When optimizing style settings for embroidery, it is crucial to consider elements such as stitch kind, density, padding, pull compensation, and enrollment. Sew type selection affects the overall appearance and feel of the style, with choices like satin, fill, and running stitches offering different structures and effects. Thickness refers to the spacing and density of stitches, influencing the style's coverage and longevity. Correct padding stitching offers security and protects against fabric distortion, particularly for intricate layouts or on elastic materials. Draw payment adjusts for textile stretch during sewing, making sure precise layout replication. Enrollment setups align various elements of the layout accurately, keeping general layout stability. By fine-tuning these layout settings, embroiderers can boost the high quality and accuracy of their embroidered creations.

Troubleshooting Common Digitizing Issues

When encountering typical digitizing issues during the needlework process, it is necessary to understand the source and carry out effective options promptly. One typical trouble is stitch density problems, where stitches might be too dense, causing the material to tighten, or also sparse, resulting in voids in the layout. Adjusting the stitch density settings in the digitizing software can aid fix this concern.

Another frequent difficulty is string breaks throughout the needlework process. This can occur because of numerous factors such as wrong tension settings, dull needles, or utilizing low-quality string. Making certain correct maintenance of the embroidery machine, including routine needle modifications and stress modifications, can lessen the event of string breaks.

Moreover, design registration errors can result in misaligned elements within the embroidery design. Checking the design alignment in the digitizing software application and making required modifications before stitching can assist in avoiding this problem. By dealing with these typical digitizing problems immediately and successfully, you can make sure a smoother needlework procedure and high-quality ended up items.

Verdict

To conclude, mastering the needlework digitizing procedure needs a solid understanding of the basics, the right selection of software program, and expertise of dig this devices and methods. Optimizing style settings and repairing typical digitizing problems are important action in making sure high-grade needlework outcomes. By complying with these steps diligently, one can attain accuracy and effectiveness in the digitizing process.

Report this page